Free CAD Designs, Files 3D Models | The GrabCAD ...

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

WhatsApp)

WhatsApp)

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

Filter: advanced process control analysis ball mill ball mill drive cement cement burner cement grinding cement production cement rotary kiln clean clinker cooling co2 emission ecs/processexpert expert system fabri fabric fabriclean filter flsmidht fl fl maag gear fl; energy efficiency gas gear overhaul gearbox replacement ...

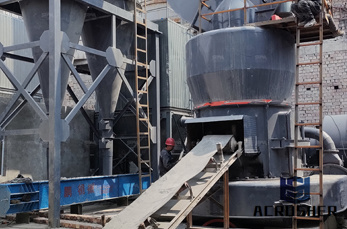

This is why the special requirement made on a gear unit for vertical mills is its reliability. And for this reason, the worldwide tried and tested bevel planetary gear units (Flender KMS, KMP, KMPS, and KMPP) are top quality to many operators of vertical mills, in particular, when a costoptimized constantspeed drive is required.

two stage gearbox for a coal mill grinder. Coal Mill Drive Gearbox gearbox of 8 5e coal mill . david brown coal mill gearbo for 8 5 e kleinejanamsterdamnl. 8 5 e coal mill gear box of david brown hydraulic system, DavidBrown gearbox, 965/40 rpm, and drive motor, 228 kW, 984 rpm, 6 gearbox of 8 5e coal mill E Mill Gear Box for Coal Grinding in in ball mill function of gear ...

The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party users.

Siemens has been awarded a major order for thirtythree KMP 450 coal mill gear units by L and TMHI Boilers Private Limited. The Indian company, a joint venture by Larson and Toubro (L and T) and Mitsubishi Heavy Industries (MHI), is based in Mumbay and specializes in the construction of energyefficient power plants.

Power Transmission Products Solutions for Coal Mining Coal Mining Overview. ... thousands of those solutions are at work right now conveying coal. From the quiet workhorse gear drive that keeps the conveyor moving at precise speeds, to the critical link of the coupling that ... It does not matter if you mine coal for a steel mill in China or ...

A horse mill is a mill, sometimes used in conjunction with a watermill or windmill, that uses a horse engine as the power source. Any milling process can be powered in this way, but the most frequent use of animal power in horse mills was for grinding grain and pumping water. Other animal engines for powering mills are powered by dogs, donkeys, oxen or camels.

A maintenance or auxiliary drive that is tailored to your requirements rounds out the scope of supply for your MAAG® WPU gear unit. The maintenance drive is placed between the motor and gear unit and allows you to rotate the mill table very slowly.

Coal Mill Gearbox Three Stage Speeds Gearbox Of Coalmill gearbox of e coal mill germany bondhumalin two stage gearbox for a coal mill grinder two stage gearbox for a coal mill grinder XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill ...

This paper analyzes the common problems of the coal mill mill drive gearbox, and introduces the causes and treatment methods of the wear and tear of the thrust mill of the coal mill mill drive gearbox. Key words: vertical coal mill; mill drive gearbox; thrust tile; wear analysis 1. Introduction to coal mill The RM1500 coal mill is a medium ...

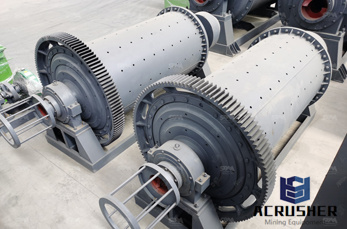

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls.

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates. Further pulverization is ... worm gear drive. Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal.

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

Jun 05, 2013· We provide optimized mill drive solutions for all types of ringgeared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and ...

Horizontal Ball Mill and Inching Drives David Brown. Our MDX range includes all elements of a horizontal ball mill drive system, these ... mill drive system; girth gear, pinion, mill drive gearbox, couplings, brakes,...

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor. The motor is fed by a fuseless cycloconverter that is connected to the MV ...

Srp Coal Mill Gear Box. ... Gear Unit To Drive Your Vertical Roller Mill FL. Gear unit for all kinds of vertical roller mills even coal millsur compact maag wpu bevel and planetary gearbox is your ticket to reliable power transmission in your vertical roller millith two series to suit your requirements, the maag wpu twostage gear unit is ...

For years, wind turbine manufacturers have been searching for ways to make direct drive turbines competitive with gearbox turbines. Direct drive technology has been praised for its design, which ...

GBS Gearbox Services international is the fastest, full service, worldwide specialist in gearbox repair of Santasalo gearboxes. Taking the latest innovations of our gearbox service experts, our goal is to get, often mission critical, gearboxes back into production at the shortest timespan possible.

GBS Gearbox Services international is the fastest, full service, worldwide specialist in gearbox repair of Flender gearboxes. Taking the latest innovations of our gearbox service experts, our goal is to get, often mission critical, gearboxes back into production at the shortest timespan possible.

Reliable coal pulverizer performance is essential for sustained fullload operation of today''s power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW''s pulverizers, found at .

Elecon has thus with its marketing network and execution capabilities, made its presence felt through consistent and satisfactory performance of its equipment and successful delivery of projects in core sectors as fertilizer, cement, coal, power generation, mining, chemical, steel, port mechanization, minerals metals processing, etc.. Learn More

Access Google Drive with a free Google account (for personal use) or G Suite account (for business use).

WhatsApp)

WhatsApp)