Grinding Media, Milling Balls, Ceramic Grinding Media, Beads

Nov 19, 2019· Grinding media Grinding media is used in wet milling and dry milling operations. Grinding media is usually a bead of uniform size, shape and density. Media is .

WhatsApp)

WhatsApp)

Nov 19, 2019· Grinding media Grinding media is used in wet milling and dry milling operations. Grinding media is usually a bead of uniform size, shape and density. Media is .

This will normally improve the dispersion. Smaller and/or harder beads ( zircon oxide or steel) can also improve the dispersion result. Further, the bead charge can be increased to about 80%. In order to operate the bead mill economically, dispersion should be made with as much solid matter as possible.

Oct 04, 2011· Wal Engineers Liter Bead Mill comprised with mm high density Zirconium Beads and 15 hp motor. Single pass or circulation further information contact at or ...

Wet milling using YTZ zirconium beads of size mm. What is the best method to filtrate those beads from the suspension? After wet milling using those very small beads, we find a problem with ...

When the steel has minor scaling on its surface and/or high travel speeds are not required, you can use solid wire with little trouble. Keep in mind that welding over mill scale with solid wire makes the arc susceptible to inconsistencies, producing spatter that requires postweld cleaning. Metalcored Wire.

Nov 07, 2019· Formulations of suspensions to be produced by wet milling are becoming more diverse and exacting. At the same time, the pressure on costs, especially in highvolume production, has continued to rise. The DYNO®MILL UBM series with the patented agitator DYNO®DISC BC is a new agitator bead mill designed to answer the demand for high production capacity, adaptability to a wide .

bead mill the DYNO ® ... the wet bead milling DYNO®MILL. Figure 3: Paths to Nanoparticles NUMBER OF BEADS vs. DIAMETER Since the count of beads (grinding media) greatly increases as their diameter decrease, there are more contact points, more collisions, and more active surfaces involved with the ...

Oct 17, 2019· Rotor Pin Type Agitator Bead Mill for fully continuous wet grinding of various products, both in circulation and pass processes. Rotor Pin Type Agitator Bead Mill for fully continuous wet ...

Apr 21, 2015· NETZSCH Agitator Bead Mill ALPHA The next Generation in Wet Grinding NETZSCHFeinmltechnik has now developed the new ALPHA modular machine platform. Compared to earliergeneration machines ...

Jun 11, 2003· Solid Ceramic End Mill comes in 4 or 6fluted versions. Laboratory and Research Supplies and Equipment Bead Mills reduce particles to submicron sizes. Laboratory and Research Supplies and Equipment Chia Seed Grinder reduces oil seeds to fine powder. Laboratory and Research Supplies and Equipment Wet Mill has highshear design.

Why I cannot get Alumina particle in nanosize scale using ball milling method? Several milling sessions using 5mm, 1mm and mm grinding ball were carried out to produce alumina nanoparticle ...

Nov 10, 2014· Chongqing Degold Machine Co., Ltd. in China produce the totally ceramic horizontal bead mill/sand mill for inkjet, inks, paints wet grinding. ZM20SB5511E ceramic horizontal bead mill is .

The 1st question to ask is the phase in which the milling must happen. If it is in wet phase, the choice will be mainly towards an agitated ball mill or, if the milling is easy and the size reduction expected not too important, a colloid mill

Currently, the pharmaceutical industry faces considerable challenges associated with the increasing number of poorly watersoluble drugs coming through the drug discovery pipeline, .Despite promising pharmacological activity, many of these drug candidates fall under class II of the Biopharmaceutics Classification System (BCS), characterized by high membrane permeability but low aqueous ...

What is a Mill Finish? (with picture) · Mill finish aluminum is kind of expensive, but it''s the perfect texture for painting. I know a lot of metalwork artist use scrap metal, but if I use mill finish I get more control over the end result.

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved. On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the ...

Due to the synergies between ceramic and glass grinding beads, we are specialists in the field of wet grinding. Our extensive knowhow in wet grinding technology enables us to optimize our glass beads for the use as grinding beads. Moreover, we use agitator bead mill grinding beads in our production and in our technical centre and thus can ...

Bead Mills. Horizontal Bead Mill. These mills use small grinding media to act against cells. The DYNO®MILL uses agitator discs inside an enclosed chamber to whip the beads into a highshear frenzy which then collide with the cells and produce breakage.

NETZSCH offers a variety of technical seminars and training opportunities made available to you. We provide extensive training, and can answer all of your theoretical and practical questions regarding the operation of wet and dry mills, mixers, homogenizers, and classifiers.

Energy is transferred from the disk to the fluid in the mill and the product is sheared by the surface of the media rather than by the disks. Media is uniformly distributed and there is little physical attrition. Some advantages of horizontal mills in wet milling incl. Highly efficient use of small amounts of media

The ball mill can grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantages.

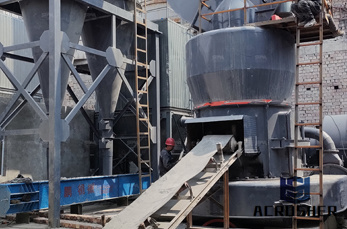

Not every mill can do this job. The mill commonly used to reliably reduce coarse particles to nanosize — whether by dispersion or comminution — is the agitator bead mill, as shown in Figure 1. An agitator bead mill consists of a grinding chamber, an agitator consisting of a rotating shaft equipped with agitator elements, a drive motor, and ...

Feb 01, 2007· Removing Rust, Mill Scale And Oils In One Step I always see the typical pretreatment stages to be a cleaner, rinse, phosphate, rinse, sealer, rinse or not. Nowhere do I see anything to deal with the rust and mill scale from the HRS steel.

Keep your rolling mill machine well maintained and oiled. Remove any marks on the rollers. Clean with a damp cloth and acetone to remove dirt. For more stubborn marks, carefully remove with fine wet and dry paper and fine steel wool. Keep the mill covered when not in use to protect the rollers from any workshop debris.

WhatsApp)

WhatsApp)