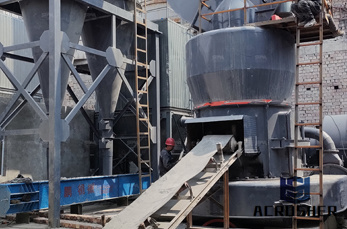

Raw Mill,Raw Mill In Cement Plant

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

WhatsApp)

WhatsApp)

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

Vertical roller raw mill capacity upgrade Now it''s possible to increase the capacity of a vertical roller mill by up to 15%. Simply integrate a specially adapted Hydraulic Roller Press (HRP) to boost output.

Sep 24, 2019· In the ore machinery pulverizing equipment, the gypsum fine Vertical Roller Mill Manufacturer is a kind of fine grinding machinery equipment aimed at the gypsum deep processing production enterprise, its design has been optimized, may display the ...

Jul 04, 2019· CHAENG is specialized in manufacturing spare parts for vertical roller mill. The grinding table is the key part of vertical mill, mainly composed of table body, lining plate, press block ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Aug 30, 2019· It is known that the vertical mill grinding roller is a key component of the vertical roller mill. Due to the complex composition of the material, often containing some hard impurities, such as stones and iron, it likely to cause severe wear on grinding roller during longterm.

Vertical Roller Mills. The criticality of the power generation industry means that gear system reliability is key. Designed in close cooperation with mill manufacturers, our vertical roller mill drive series demonstrates long bearing life, high power density and an optimised product lifecycle.

Increase in usage of vertical mills in various industries such as cement, coal, slag grinding, desulfurization industry, etc. due to rapid industrialization and technological advancements in mill manufacturing technologies and processing equipment are the key trends propelling the vertical roller mill .

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Separation operation of verticalrollermill will be modelled by application of current models. The model shall enable the prediction of the throughput, the particle size distributions around the verticalrollermill circuit, the specific energy consumption and in a later stage the wear to .

Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill. If needed, the roller swingout feature allows easy removal of rollers to perform maintenance work of common parts is possible across different vertical roller mill sizes for both cement and raw applications.

The SIMA mill combines the drying, grinding and separation processes into just one unit, which simplifies the plant layout. And because it operates at a low noise level, outdoor installation is feasible – substantially reducing civil construction costs and improving the working environment.

Vertical roller mill more and it covers an area of small, low power consumption, light weight, low noise, high efficiency, considerable economic benefits recognized the benefits of the construction materials industry. vertical roller mill is our main product, while the rotor is an essential component of the vertical roller mill selection ...

The grinding Table of Vertical Roller Mill is one of the key parts of vertical roller mill. It includes drag rings, segments (lining plate) and bases. The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodi

Grinding roller is core part of vertical mill. SYMMEN METAL Casting can provide customized service according to customers''different processing requirements. Besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc. We gained good reputation from customers.

We manufacture different wear and impact resistant parts for your vertical mill, for example: roller tire, segmented rollers, table liners and nozzle suitable material selection we offer hard weld deposit and other special applications to increase the surface hardness.

The grinding table is one of the key parts of vertical roller mill It includes drag rings, segments (lining plate) and bases The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome the deficiencies in structure and make the grinding base bear force equivalently All ...

grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system. However, despite these benefits, applications of the vertical roller mill .

Verical Roller Mill. Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design.

I see that several have answered based on dry grinding, Vertical Roller Mill vs. conventional Ball Mill. If we instead focus on wet grinding, we should differentiate between stirred media grinding, which can be both vertical and horizontal, and tumbling mills with manufactured grinding bodies.

Vertical Roller Mill China Stone Crushing Equipment. Vertical Roller Mill Unique Benefits. The final products has little iron and the whiteness and purity are quite high. It is quite environmentally friendly, LUM is of little dust and noise. Vertical roller mill use PLC/DCS automatic control system, well save the cost of operators. Get Price

Vertical Roller Mill (VRM) The power used for the actual grinding process while grinding raw materials, depends mainly on the hardness of raw materials and the type of mill used, ball mill or vertical roller mill. Typically, the motor of the ball mill consumes about 14 .

Grinding table is one of key parts of vertical roller mill. It includes drag rings, lining plate and base. The optimization and improvement are made basing on traditional grinding table casting technology, that the most advanced sodium silicatebonded sand molding technology, to overcome deficiencies in structure and make the grinding base bear force equivalently.

The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance. Learn more about the features of the Williams roller mill crushers to see why they should be your top choice.

WhatsApp)

WhatsApp)