Coal Fired Power Plant YouTube

Nov 26, 2013· In coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. The coal is pulverized into ...

WhatsApp)

WhatsApp)

Nov 26, 2013· In coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. The coal is pulverized into ...

(60 MW) and the lowest heat rate (11,700 Btu/kWh) of any biomassfired power plant. Biomasscofired coal plants can achieve slightly lower heat rates, as exemplified by Greenidge Station (11,000 Btu/kWh on the biomass portion of the fuel, compared to 9818 on coal alone). The least efficient plants in this report have heat rates of about 20,000

May 09, 2019· In total, 289 have closed since 2010, comprising 40 percent of the US''s coal power capacity, while an additional 241 plants remain open. A coal power plant .

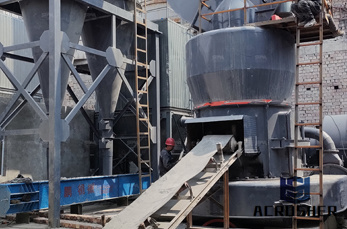

Crusher Mill For Coal Fired Power Plant Working. How A Coal Pulverizer Works Coal Grinding Process 3D ... Feb 23, 2010 Here''s a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in .

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine.

Roberts said, "There are 1,600 new coalfired power plants being constructed as I speak around the world." A New York Times article from more than two years ago cited the 1,600 figure, but even ...

Tha Tum in the neighborhood of power plant and pulp and paper mill at a distance of 2 km. The site of fish sampling, Shalongwaeng Canal, is adjacent to a coalfired power plant (upper left), an openair coal storage pile (upper right), a pipeline transporting coal across the canal

This is all controlled by the coal mill or pulveriser, and its associated feeder equipment. Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output. For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand ...

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Coalfired plants have been powering the electric grid for more than a hundred years, but the technology being used in them is not stagnant, as many advancements have been made.

Feb 20, 2017· Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standa...

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

In the United States, three coalfired power plants reported the largest toxic air releases in 2001: Duke Energy Roxboro Steam Electric Plant in Semora, North Carolina. The fourunit, 2,462 megawatt facility is one of the largest power plants in the United States.

A possible mode of operation that was tested in a coalfired power plant and that might meet the new requirements is the socalled onemill operation. Due to their solid design, in particular, older plants are well suited for this approach. They are often designed with an optimal reserve potential.

May 04, 2011· The Cost of CoalFired Power Generation. Coalfired power stations are relatively expensive to build because their construction involves both large quantities of expensive materials such as iron and steel and large volumes of labour. Although some parts of a coalfired power plant such as its steam turbines can be assembled in a factory and ...

Introduction to Coal handling plant. In a coal based thermal power plant, the initial process in the power generation is "Coal Handling".So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station.

This is all controlled by the coal mill or pulveriser, and its associated feeder equipment. Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output. For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand.

By Steve Coulombe, Product Manager for DSI mills at Sturtevant. Operators of coal fired power plants have a lot to worry about today: The price of coal relative to natural gas, stack emissions ...

Advantages of coalfired power plant: It''s known that coal is the most widely used fuels for generating power and electricity around the world which means that the coal_fired power plant has many advantages as: It''s abundant and easy to burn. It doesn''t depend on the weather or existing climatic conditions for mining coal.

Coalfired power operators continue to look for ways to increase the efficiency and extend the working lives of their plants by improving operational flexibility and reducing environmental impact. Two possible options are explored here: combining solar energy with coalfired power generation, and cofiring natural gas in coalfired plants.

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

Jan 24, 2020· Commercial Liability Partners (CLP) announces purchase of the Monticello Power Plant and the Big Brown Power Plant, two retired coalfired power plants in Titus County and Freestone County, Texas. Commercial Liability Partners (CLP), announced the purchase of Dynegy''s retired coalfired power plant located in East Alton, Illinois.

Jan 13, 2020· (Reuters) coalfired power plants shut down at the secondfastest pace on record in 2019, despite President Donald Trump''s efforts to prop up the industry, according to data from the ...

Coal is fired in the boiler to generate heat. Alternatives fuels, pet coke, etc. can also be used as fuel. The hot flue gases containing fly ash is passed through a baghouse to separate the flyash before allowing the flue gases into the atmosphere through the stack.

WhatsApp)

WhatsApp)