crushing grinding and flotation of nickel

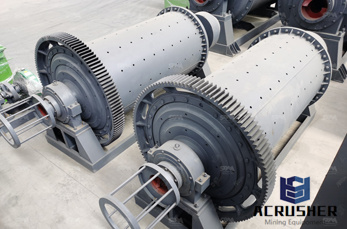

Nickel Ore Nickel ore is the main material for steel plant. Natural nickel ore will be made to iron after crushing, grinding, magnetic separation, flotation, reelection and other...

WhatsApp)

WhatsApp)

Nickel Ore Nickel ore is the main material for steel plant. Natural nickel ore will be made to iron after crushing, grinding, magnetic separation, flotation, reelection and other...

Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used. The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel ...

Abstract: In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing % Ni, % Co, % Fe, % MgO, and % SiO2 was collected in the Mojiang area of China. Garnierite was the Nibearing

Regrinding reagents and helped to reduce Magnetic Properties and Separation Potential Wet, highintensity magnetic separation (WHIMS) was considered as a poten tial method for removing the cobaltnickel mineral from the chalcopyrite con centrate.

Since Kim et al. (2010) reported upgrading of Ni laterite using roasting and magnetic separation, magnetic separation was tested on the three Ni laterite samples using both a low intensity ( ± T) dry magnetic separator and a Wet High Intensity Magnetic Separator (WHIMS) unit. Roasting tests ead of dry, low intensity magnetic ...

Natural nickel ore will be made to iron after crushing, grinding, magnetic separation, flotation, reelection and other... Get price. Minerals Engineering Conferences Home. ... See sulphide ore, then crushing or grinding mill ... Nickel and Copper sulphide ores need further crushing ... various stages: flotation, blast furnace, smelters,.

Phosphate Rock Nickel Ore Magnetic Separation. Manganese Ore Magnetic Separation Production Line. manganese ore including two stages rough separate the highintensity magnetic ore and concentrate PhosphoritePhosphate Rock Flotation Equipment Production Line flotation is the main beneficiation method when processing copper sulfide nickel ore magnetic separating and

Nickel Separation Grinding And Magnetic Nickel Separation Grinding And Magnetic. magnetic separator for nickel ore fairytime. nickel separation equipment petpantrymiorg nickel separation grinding and magnetic makabsworg 13 May .

In this study, segregation roasting and magnetic separation are used to extract nickel from a garnierite laterite ore. The garnierite laterite ore containing % Ni, % Co, % Fe, % MgO, and % SiO2 was collected in the Mojiang area of China. Garnierite was the Nibearing mineral; the other main minerals were potash feldspar, forsterite, tremolite, halloysite, quartz, and ...

The magnetic strength of the raw magnetic material is measured in megagauss oersteds (MGO). This number will change as the magnet is integrated into a piece of separation equipment. By manipulating the north and south magnetic poles on the magnets thru placement and the use of steel pole pieces or back plates, the magnetic field is enhanced and ...

Nickel primary crusher indonesia. nickel ore crushing equipment in Indonesia PE Series Jaw Crusher Based on long experience and high technology Zenith developed PE series jaw crusher with several different models which can meet various crushing requirements in primary and secondary crushing

Nickel Separation Grinding And Magnetic. nickel separation grinding and magnetic. Nickel Separation Grinding And Magnetic Founded in 1997, Shandong Xinhai Mining Technology Equipment Inc, under Xinhai is a stockholding high and new technology. Get Price And Support Online; NICKEL RECOVERY FROM ELECTRIC ARC FURNACE.

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

magnetic separation of nickel . separation nickel magnetic lsesuconservatives eu magnetic separation of nickel – Grinding Mill China Magnetic 167 Magnetic Separation of Free Metals As discussed in the section on asteroid resources asteroids are rich in free nickel iron metal granules Get Price magnetic separator for nickel ore 100 customer reviews Inquiry

The target of the current work is to investigate the possibility of nickel recovery from EAF slag by magnetic separation. To meet the target, the effect of the following parameters was studied: grain size, magnetic field intensity, thickness of slag layer, moisture content, and regrinding .

Nickel Ore Magnetic Separation, Nickel Ore Magnetic ... About product and suppliers: Alibaba offers 109 nickel ore magnetic separation products. About 22% of these are mineral separator. A wide variety of nickel ore magnetic separation options are available to you, There are 29 nickel ore magnetic separation suppliers, mainly located in Asia.

Mar 01, 2020· Nonmagnetic nickel slag was prepared by the magnetic separation of nickel smelting slag with a dryroll magnetic separator (magnetic separation intensity 2000–12,000 Oe). Fig. 8 shows the particle size distribution of nickel slag after magnetic separation. The particle size of the sample was nearly the same.

Nickel ore divides into copper sulfide and copper oxide ore the main process for copper sulfide is flotation magnetic and gravity separation is the subsidiary process It is a high technological enterprise that integrated research manufacture sales and service The company has multiple subsidiaries such as Mineral Processing Research Institute

To study the effect of regrinding on the quality of the magnetic product, the + mm size fraction of the slag was reground to in a roll crusher. The magnetic separation was carried out in the same way as that concerning the effect of slaglayer thickness. The results of magnetic separation after regrinding are shown in Table 5.

In the end, you can recover the metals by means of crushing, grinding, flotation and magnetic separation. Besides, leaching one or two metals from the matte also can .

Aug 01, 2015· Since Kim et al. (2010) reported upgrading of Ni laterite using roasting and magnetic separation, magnetic separation was tested on the three Ni laterite samples using both a low intensity ( ± T) dry magnetic separator and a Wet High Intensity Magnetic Separator (WHIMS) unit. Roasting tests ead of dry, low intensity magnetic ...

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet. In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as ...

nickel separation grinding and magnetic .nickel separation grinding and magnetic. magnetic separation mining copper Feldspar . magnetic separation mining copper XSM excellent mining the Read More. Magnetic PERMANENT§ Magnetic Separation of Free Metals. As discussed in the section on asteroid resources, asteroids are rich in ...

Magnetic separation of leadcopper rougher flotation concentrate. 6 5. Percentage of 100 by 200mesh siegenite solubilized in 2 hours at 1000 c ... Grinding The cobalt and nickel found in the Missouri Lead Belt ore have been charac ...

WhatsApp)

WhatsApp)