(PDF) Pebble milling option for reduced throughput

Pebble milling option for reduced throughput. ... pebble" mill circuit" would be in order of 50 to 60% of the current ball mill circuit configuration. The profitability of the Veliki Krivelj ...

WhatsApp)

WhatsApp)

Pebble milling option for reduced throughput. ... pebble" mill circuit" would be in order of 50 to 60% of the current ball mill circuit configuration. The profitability of the Veliki Krivelj ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

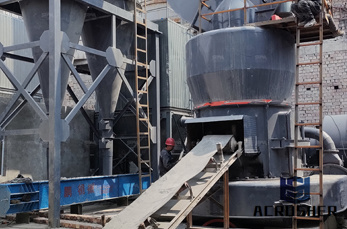

Mar 28, 2016· The whole structure of Raymond mill is composed of a rolle mill,Driving system, Classifier, pipeline device, blower, finished cyclone collector, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric motor . the Raw materials by...

Working Principle of Pebble Mill. Materials are fed into the mill at a fixed flow rate along the shaftless screw of the screw conveyor. Once inside the first compartment of the drum, the motor is activated and rotates the drum via a gearbox.

A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell. The nanostructure size can be varied by varying the number and size of ...

Pebble mills are similar to ball mills except that the grinding media is closely sized rocks or pebbles. Pebble milling is a form of autogenous milling as no steel media is used in the process however, the type of rocks used are selected more carefully than in convention AG milling.

A milling machine which has a ram on the top of the column is called ram type milling machine. pebble mills milling The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill.

Mar 27, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . Ball and Pebble Mills: The expressions "ball milling" and "pebble milling" are frequently used interchangeably. Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses

Working Principle Jet Milling is a . High precision, electronic pressure controls that monitors the micronizer proportional pressure regulator; Mini PLC system; ... Working principle of pebble mill – CGM mining application. Grinding Mill/Gold Ore Ball Mill/Chromite Rod Mill Working Principle: . stone micronizer/stone pulverizder Working ...

Pebble mills are similar to ball mills except that the grinding media is closely sized rocks or pebbles. Pebble milling is a form of autogenous milling as no steel media is used in the process however, the type of rocks used are selected more carefully than in convention AG milling.

Apr 23, 2015 ... Operation Instructions For Cement Grinding Ball Mill Of Dry Cement Plant, ball ... is the working principle of ball mill?what are its features Ball Mill Working principle: When ... temperature mill ing operations, or pebble milling. Get Price

pebble mill working principle . So he can plan rice mill in a manner that Bank gives inprinciple approval based on the Metadata Management from a boulder to a pebble Pebble Mill Working Principle Crusher USA. 201457working principle of line wet ball mill. pakistan ball mill, india ceramic Pebble mills are similar to ball mills except that the grindin

Stoneware Process Equipment for Milling, Grinding, and Blending. Tradition of Quality A History of Service . Stoneware was founded in 1865 and manufactures its products in a 70,000 sq. ft. facility located just south of Youngstown, Ohio. Early in its history, Stoneware developed an expertise in formulating ceramic materials ...

Size Reduction. Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a wet or dry Mills are referred to by many names including Pebble Mills, Tube Mills and Attrition Mills, but no matter what the nomenclature they all operate on the same efficient principle.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

pebble mill working principle Henan Deya Machinery Co., Ltd. Pebble mills are similar to ball mills except that the grinding media is closely sized rocks or pebbles. Pebble milling is a form of autogenous milling as no steel media is used in the process however, the type of rocks used are selected more carefully than in convention AG milling.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Every mining operation has a unique grinding process. Variable needs require versatile grinding equipment. offers flexible autogenous (AG) mills, semiautogenous (SAG) mills, ball and pebble mills, as well as stirred mills to fit your needs.

Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughput. The effect of feed size is marked, with both larger and finer feed sizes ...

Pebble mills also known now as ceramic lined mills are a type of ball mill and are used in the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, minerals for ceramics and semiconductor materials down to 1 micron or less.

Toggle navigation MILL Home Products Solutions Project About Contact working principle of pebble mill principle of pebble milling ... mill_mill____ mill pebble internal ... Objects made of or work done in wood,... The uniformitarian principle, like any other ...

WhatsApp)

WhatsApp)