SAG Mill Control: It Shouldn''t be that Hard

Download Citation | SAG Mill Control: It Shouldn''t be that Hard | The use of advanced control in the plant control systems (PCS) such as programmable logic controllers (PLC) or distributed control ...

WhatsApp)

WhatsApp)

Download Citation | SAG Mill Control: It Shouldn''t be that Hard | The use of advanced control in the plant control systems (PCS) such as programmable logic controllers (PLC) or distributed control ...

sag mill control in south africa Stone Crushing Equipment The building aggregates equipment of AC includes not only a series of single equipment of coarse crushing, intermediate and fine crushing, sand making and shaping, but also a batch of standardized design products of production line on the basis of many years of experience.

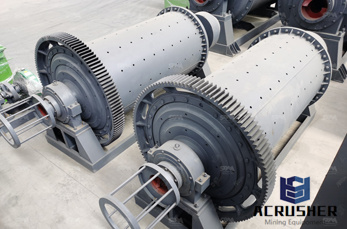

Planetary Ball Mills for fine grinding of soft, hard to brittle or fibrous materials . Dry and wet grindings are possible. . ... this new Pacifica control box and foot . Ball Mill Jars and Balls . Wet Storage Jars . ... The wet grinding plant for gold ore consists of an SAG mill and a ball mill. . 4,500 KW COMBIFLEX drives and has a rated ...

SAG mills of comparable size but containing say 10% ball charge (in addition to the rocks), normally, operate between 70 and 75% of the critical speed. ... Table shows the simulated work index of the blend of hard and soft ore types. The computer simulation underestimated the value of the work index by approximately 1 kWh/t. ... As the fuel ...

The results of the conventional comminution tests indicated a wide range from soft to very hard ore, even within the same rock type. ... (BBWi) and the A x b parameter used for SAG mill circuit design. The hardness values also showed a positive correlation with potassium and sodium in all rock types. This is strongly suggestive of a ...

For the mining industry, our semiautogenous (SAG) grinding mill uses a minimal ball charge in the range of 615 percent. It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries. Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding media.

SAG Mill Grinding Circuit Design. SAG mill control fundamentally means managing the load in the mill by adjusting the feed rate of ore to the mill and/or manipulating the rotational speed of the mill. The best way to measure load is to mount the mill on load cells.

Highlights A multicomponent (2D) AG/SAG model has been developed. The model relies on independent breakage and discharge rates for each component. The model was validated using pilot plant and industrial survey 2D data. The model accurately described the effect of feed composition on mill performance.

JKMRC researchers tackle SAG mill fill productivity challenge with new ''soft sensor'' Posted by Daniel Gleeson on 3rd April 2020 Researchers from the Sustainable Minerals Institute''s Julius Kruttschnitt Mineral Research Centre (JKMRC) say they are developing a soft sensor to overcome previouslyaccepted performance challenges facing SAG mills.

Jun 06, 2019· The semiautogenous grinding (SAG) mill at the Phoenix Mine is the largest SAG mill in the United States. "This is a lowgrade deposit, so volume is .

Variable Speed . Single or double pinion driving systems. Designed to drive and control the speed of the medium voltage motors coupled to the SAG/AG, ball and HPGR mills with single or double pinion, the MVW01 frequency drive uses state of the art technology through a multilevel structure with medium voltage IGBTs, reducing the harmonic currents on the motor to extremely low levels.

Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the .

Ag Sag Milling Control Grinding Mill China. Low Broken Rate Sag And Ag Mill Grinding Media. Factory Directy Sale Low Price Sag and AG Mill Special Use grinding media ball . Bre if Description are manufacturer and exporter of grinding balls in China,with the annual output of .

Typically, a SAG mill based circuit (P80 of 106 to 150 um) has media costs of around A1/t. Providing the ore is amenable, the use of primary autogenous milling can reduce this cost by 40%. Autogenous milling is typically practiced in association with

installed to control the SAG mill charge. The project also included an ... hard, to maximise impact breakage while highe r loads are selected . when the ore is soft, to maximise the generation of ...

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Application of HPGR in ''hard rock'' comminution circuits is relatively new although several kimberlites (up to 15 kWh/t) and lamproites (up to 18 kWh/t) are every bit as hard as the typical copper ore (15–16 kWh/t). Patzelt et al. (2001) showed that ''HPGRs have proven themselves in AG and SAG mill circuits in the iron ore industry ...

Our unique Outotec TPL™ technology improves grinding process efficiency – the primary grinding process can be intensified for hard ores and material transport can be improved for soft ores. TPL is an environmentally friendly technology used to achieve higher energy efficiency from the grinding mill.

For AG and SAG milling, it can be demonstrated that there is an optimal blend of hard to soft components in feed, and any optimal blending condition is both oredependent and millspecific. The new modelling approach addresses the challenge of establishing this blend by providing a quantitative prediction of the influence of blending soft and ...

SAG Mill Control: it shouldn''t be that hard An economically appealing method for improving operations is available without the capital expense — get more out of a mill by applying the advanced control capabilities in the existing plant control system.

CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): The difficulty of stabilizing SAG mill load limits the effectiveness of feedback control approaches. Control is particularly difficult during periods when the feed ore is either unusually hard or fine. There is also a strong tendency to lose control during transient periods when feed ore changes.

Sag Mill Circuit In Iron Ore Mining Machinery. A Summary of the News: Easily share your publiions and get them in front of s Eloranta, J 2001 Optimised iron ore blast designs for AG SAG Hill SAG mill circuit;Iron ore concentration plants play an important role in After primary crushing, the gold ore is fed into the SAG mill along ...

Speaker: Dr Francisco Reyes, Research Fellow, JKMRC Abstract: SAG mills are a key asset for mineral processing operations as one of the critical stages of extracting mineral out of ore, and their continued stable operation is central to productivity. However, the performance of a SAG mill changes rapidly in response to conditions such as feed size and hardness as well as longerterm ...

(2020). Relationship among operational parameters, ore characteristics, and product shape properties in an industrial SAG mill. Particulate Science and Technology: Vol. 38, No. 4, pp. 482493.

WhatsApp)

WhatsApp)